Tall Parts

Another area that EDM Wirecraft has had particular

success is in cutting tall parts. All of our Charmilles machines are capable of cutting

15.75” tall right out of the box. We find that many companies just do not have the

right people or the right experience to handle jobs like this even though they may have

equipment much like ours. Our years of experience with Wire EDM and the many unusual jobs

that we have tried over the years enable us to take full advantage of what our machines

will do in their standard configuration.

Another area that EDM Wirecraft has had particular

success is in cutting tall parts. All of our Charmilles machines are capable of cutting

15.75” tall right out of the box. We find that many companies just do not have the

right people or the right experience to handle jobs like this even though they may have

equipment much like ours. Our years of experience with Wire EDM and the many unusual jobs

that we have tried over the years enable us to take full advantage of what our machines

will do in their standard configuration.

Where

many shops may feel that a 10-12” tall part is tall, we find this to be relatively

normal. At 15.75” tall, things are just starting to get interesting, 20” keeps

our attention, and at 25” we are paying pretty close attention to what is going on.

How thick

can you cut? That is a question we often hear. I always give the customer (or potential

customer) the same answer. I don’t know. Years ago we had a machine that would cut

6” thick. We had a customer that told us he could give us a lot more work if we could

cut 12 “ thick. We did a little engineering, modified some parts, and worked all

weekend  to make the necessary modifications. We

finished up on Monday morning and got the machine back into service that day.

to make the necessary modifications. We

finished up on Monday morning and got the machine back into service that day.

The next

day, Tuesday, the same customer called and asked if we could cut 12.375” tall.

Needless to say we were not going to let 3/8 of an inch stop us. That machine went on to

cut as much as 16” thick and is still running in our shop today. It no longer is used

for parts that tall, but it got us on our way with tall parts. Back to the original

question, “How thick can you cut?” I still don’t know because I cannot

predict what a customer may bring in the door tomorrow.

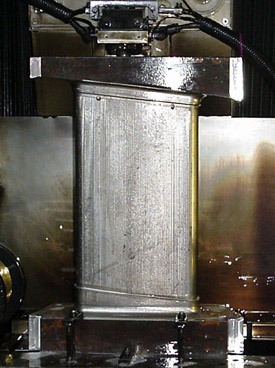

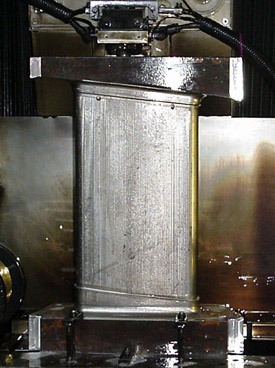

On this page you will see three

different parts. The one at the top of the page is 22” tall. We do these in fairly

large quantities and have very little trouble with them. That was not always the case. It

took much experimenting, engineering, and working with parameters to make this job

feasible. Even though this part is 22” tall, we don’t really think of it as a

“tall” part. By now it has become just another part that we run.

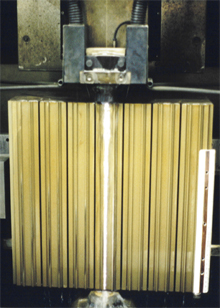

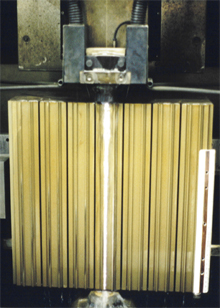

On the

left center of this page you will see a mold core about 15” tall. This core has

several intricate slots that have much detail on them that go into the core about

1.5” from the top. ( The side we see the wire sparking on. ) This part was a good

candidate for Wire EDM mainly because of the amount of detail in these slots and the fact

that the Wire EDMed surface would save the customer a lot of polishing time. Could this

core have been made other ways? Sure. Almost anyone in the mold making business knows that

there is seldom just one way to arrive at the same end. This just happened to be the path

that worked out for this particular customer.

The part

at the bottom of the page is a H-13 mold core 17” tall that we cut a number of years

ago for a customer. The mold had a lot of pieces that fit together to form what was to be

the part area. We cut this and many other components on this job because this customer

felt that by using the Wire EDM process they could reduce the amount of hand work

necessary to achieve a good seal.

These are

just a small sample of the tall parts we have done over the years. Hopefully these

applications will give you some idea of how our ability to cut tall parts may be of use to

you and your company.

Another area that EDM Wirecraft has had particular

success is in cutting tall parts. All of our Charmilles machines are capable of cutting

15.75” tall right out of the box. We find that many companies just do not have the

right people or the right experience to handle jobs like this even though they may have

equipment much like ours. Our years of experience with Wire EDM and the many unusual jobs

that we have tried over the years enable us to take full advantage of what our machines

will do in their standard configuration.

Another area that EDM Wirecraft has had particular

success is in cutting tall parts. All of our Charmilles machines are capable of cutting

15.75” tall right out of the box. We find that many companies just do not have the

right people or the right experience to handle jobs like this even though they may have

equipment much like ours. Our years of experience with Wire EDM and the many unusual jobs

that we have tried over the years enable us to take full advantage of what our machines

will do in their standard configuration. to make the necessary modifications. We

finished up on Monday morning and got the machine back into service that day.

to make the necessary modifications. We

finished up on Monday morning and got the machine back into service that day.