Molds

EDM Wirecraft originated in 1988 as an

offshoot of a moldmaking shop. My training and experience prior to Wire EDM was in

moldmaking. This has been very helpful over the years in dealing with our customer

base, which is largely mold shops. We understand the moldmaking process and we can

often suggest ways to make your job easier or less costly.

EDM Wirecraft originated in 1988 as an

offshoot of a moldmaking shop. My training and experience prior to Wire EDM was in

moldmaking. This has been very helpful over the years in dealing with our customer

base, which is largely mold shops. We understand the moldmaking process and we can

often suggest ways to make your job easier or less costly.

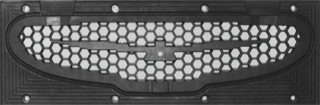

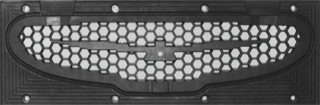

The photo

at upper left is a graphite electrode with 149 pockets through it. All of these

pockets have 3 degrees of taper on each wall and had to be cut with no chips or voids in

the electrode. The overall size of this electrode is 6” x 18” x 1.5”

thick.  We made a total of 7 of these

electrodes which where featured in EDM Today. As you can tell, this was obviously an

automotive application. Have you seen the product this mold produced?

We made a total of 7 of these

electrodes which where featured in EDM Today. As you can tell, this was obviously an

automotive application. Have you seen the product this mold produced?

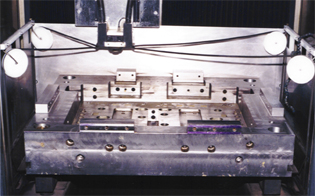

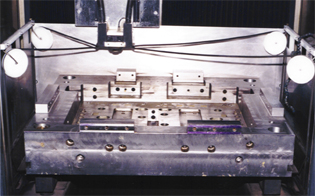

The

photo in the upper right is fairly typical of some of the work we do on medium to large

molds. We cut tapered lifter pockets, up to 45 degrees in blocks as thick as

12-14”. We can cut insert pockets as well, make the inserts when needed and do

just about anything that you would expect a Wire EDM can do, and sometimes a little more.

EDM Wirecraft originated in 1988 as an

offshoot of a moldmaking shop. My training and experience prior to Wire EDM was in

moldmaking. This has been very helpful over the years in dealing with our customer

base, which is largely mold shops. We understand the moldmaking process and we can

often suggest ways to make your job easier or less costly.

EDM Wirecraft originated in 1988 as an

offshoot of a moldmaking shop. My training and experience prior to Wire EDM was in

moldmaking. This has been very helpful over the years in dealing with our customer

base, which is largely mold shops. We understand the moldmaking process and we can

often suggest ways to make your job easier or less costly.