Extrusion Tooling

As our

customer base has expanded we have become more and more involved in the building of

extrusion tooling. At first it was something that we just stumbled upon but after

working within the extrusion industry for a period of time we realized what a perfect fit

Wire EDM was for the construction of Extrusion Dies and many other associated components.

As our

customer base has expanded we have become more and more involved in the building of

extrusion tooling. At first it was something that we just stumbled upon but after

working within the extrusion industry for a period of time we realized what a perfect fit

Wire EDM was for the construction of Extrusion Dies and many other associated components.

We have

built tooling for profile extrusion, automotive sealing and gaskets, and medical tubing in

relatively equal numbers. The largest die that we ever built produced a part that

was 22” wide and 4” tall. The smallest die that I can remember made a

piece of medical tubing that was less than 1/8” in diameter and had 5 lumens

(openings) in it.

At

EDM Wirecraft we do not claim to be experts in the design of extrusion tooling. Our

expertise is in finding ways to take an  idea

that a customer has for something that he has not been able to do before and finding a way

to turn this idea into reality. With

our capabilities for cutting tapers we have often let the engineers and designers that we

work with design a tool that was what they really wanted, and not just what they had to

settle for. Being able to provide our customers with this type of support and

assistance helps make our work very rewarding Each customer’s needs and

requirements are different and this is part of the challenge as well.

idea

that a customer has for something that he has not been able to do before and finding a way

to turn this idea into reality. With

our capabilities for cutting tapers we have often let the engineers and designers that we

work with design a tool that was what they really wanted, and not just what they had to

settle for. Being able to provide our customers with this type of support and

assistance helps make our work very rewarding Each customer’s needs and

requirements are different and this is part of the challenge as well.

Some

customers approach us with little more than a concept, while others may send us a complete

design. Most jobs seem to fall somewhere in between.

In

addition to dies we build insertion/extraction/deflection test fixtures, sizing equipment,

post forming fixtures, die heads, unusual adapters, and pretty much anything else that our

customers may need.

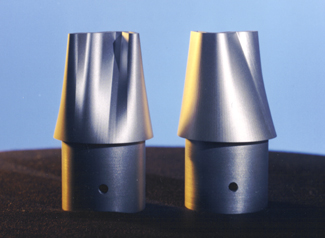

The two

upper most photos that you will see on this page are of some parts for an automotive

application extrusion die. These are guides that introduce a wire carrier into the

flow stream of material around it. We have made many of these parts in  many different styles, but I like the one piece

ones like these the best. They are often a bit of a challenge to make, but the

successful completion of a part like this tends to give one a great sense of pride in

their work.

many different styles, but I like the one piece

ones like these the best. They are often a bit of a challenge to make, but the

successful completion of a part like this tends to give one a great sense of pride in

their work.

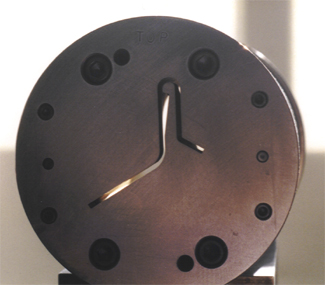

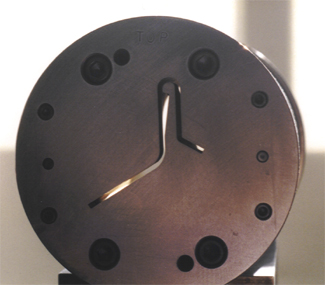

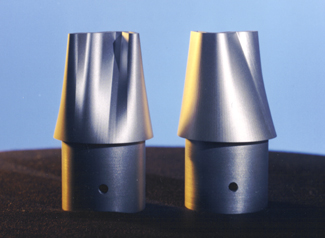

The

last three photos are of a relatively simple extrusion die that we built some years ago

and two of the slugs that came out of it during the Wire EDM process. As you can see

from these slugs, almost no taper is impossible for us to cut. With the taper

capabilities of our Charmilles Wire EDMs, we can streamline these dies in just about any

fashion imaginable. We can fatten up an area to add more restriction and direct flow

elsewhere. We can remove more material in an area that may be difficult to fill and

thereby enhance the flow to that area. Our goal is to build a high quality tool that

looks good, meets the customer’s requirements, and makes good parts. When we

can do this, we feel like we have done well by our customer.

Although

I do not have any photos, we also build vacuum sizers. Some people call these dry

sizers. We have had very good success with these and I suspect that many people who read this will have

encountered and used this type of sizer before. We work very closely with David

Friedwald of Extrusion Die Technologies, Inc. He is the creator of the concept that

we use and he works with us on a consulting basis. Dave is retired, sort of anyway,

enjoys playing with his grandchildren immensely, and has a very enjoyable time sharing his

vast knowledge of the extrusion industry with us. He will design complete die and

sizer sets if the customer so desires, and is capable of handling almost any problem that

you may encounter.

very good success with these and I suspect that many people who read this will have

encountered and used this type of sizer before. We work very closely with David

Friedwald of Extrusion Die Technologies, Inc. He is the creator of the concept that

we use and he works with us on a consulting basis. Dave is retired, sort of anyway,

enjoys playing with his grandchildren immensely, and has a very enjoyable time sharing his

vast knowledge of the extrusion industry with us. He will design complete die and

sizer sets if the customer so desires, and is capable of handling almost any problem that

you may encounter.

As our

customer base has expanded we have become more and more involved in the building of

extrusion tooling. At first it was something that we just stumbled upon but after

working within the extrusion industry for a period of time we realized what a perfect fit

Wire EDM was for the construction of Extrusion Dies and many other associated components.

As our

customer base has expanded we have become more and more involved in the building of

extrusion tooling. At first it was something that we just stumbled upon but after

working within the extrusion industry for a period of time we realized what a perfect fit

Wire EDM was for the construction of Extrusion Dies and many other associated components.

many different styles, but I like the one piece

ones like these the best. They are often a bit of a challenge to make, but the

successful completion of a part like this tends to give one a great sense of pride in

their work.

many different styles, but I like the one piece

ones like these the best. They are often a bit of a challenge to make, but the

successful completion of a part like this tends to give one a great sense of pride in

their work.