Extreme Tapers

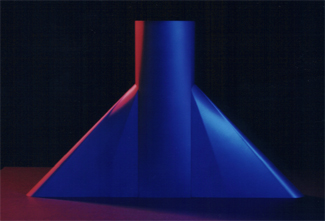

Cutting extreme amounts of taper, especially in

thick work pieces, was the thing that helped gain EDM Wirecraft national exposure. The

photo on the upper right of this page shows the slug (scrap) that came out of an extrusion

adapter that changed from a round hole to an L shaped part. This part was truly a

challenge. There are photos of the adapter itself in our photo gallery. If you have

trouble seeing how this slug came out of these two blocks you are not alone. I did it and

the photos still confuse me. When doing parts like this we are about 15 degrees past the

limit of what the machine was designed for. This has been a relatively simple modification

that has let us cut tapers as extreme as 45 degrees in any thickness up to 15” tall.

Cutting extreme amounts of taper, especially in

thick work pieces, was the thing that helped gain EDM Wirecraft national exposure. The

photo on the upper right of this page shows the slug (scrap) that came out of an extrusion

adapter that changed from a round hole to an L shaped part. This part was truly a

challenge. There are photos of the adapter itself in our photo gallery. If you have

trouble seeing how this slug came out of these two blocks you are not alone. I did it and

the photos still confuse me. When doing parts like this we are about 15 degrees past the

limit of what the machine was designed for. This has been a relatively simple modification

that has let us cut tapers as extreme as 45 degrees in any thickness up to 15” tall.

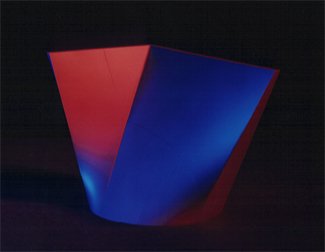

The

photo on the lower left of this page is of a job that has been featured in many magazines

and advertisements. These are the slugs that came out of a single block which measured

9.125” thick, 18” long and 6” wide. We began with an approximately

3.25” hole on one side of the 9.125” thickness and ended up with a slot on the

other side 1.5” wide X 14” long. This was one of the many projects that a

customer brought to us and asked if we could do. After a considerable amount of head

scratching, we decided that we could and from there we proceeded to cut what the customer

asked for.

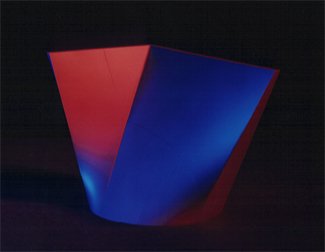

The

photo on the lower left of this page is of a job that has been featured in many magazines

and advertisements. These are the slugs that came out of a single block which measured

9.125” thick, 18” long and 6” wide. We began with an approximately

3.25” hole on one side of the 9.125” thickness and ended up with a slot on the

other side 1.5” wide X 14” long. This was one of the many projects that a

customer brought to us and asked if we could do. After a considerable amount of head

scratching, we decided that we could and from there we proceeded to cut what the customer

asked for.

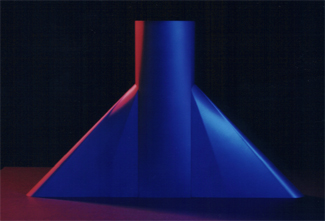

Cutting extreme amounts of taper, especially in

thick work pieces, was the thing that helped gain EDM Wirecraft national exposure. The

photo on the upper right of this page shows the slug (scrap) that came out of an extrusion

adapter that changed from a round hole to an L shaped part. This part was truly a

challenge. There are photos of the adapter itself in our photo gallery. If you have

trouble seeing how this slug came out of these two blocks you are not alone. I did it and

the photos still confuse me. When doing parts like this we are about 15 degrees past the

limit of what the machine was designed for. This has been a relatively simple modification

that has let us cut tapers as extreme as 45 degrees in any thickness up to 15” tall.

Cutting extreme amounts of taper, especially in

thick work pieces, was the thing that helped gain EDM Wirecraft national exposure. The

photo on the upper right of this page shows the slug (scrap) that came out of an extrusion

adapter that changed from a round hole to an L shaped part. This part was truly a

challenge. There are photos of the adapter itself in our photo gallery. If you have

trouble seeing how this slug came out of these two blocks you are not alone. I did it and

the photos still confuse me. When doing parts like this we are about 15 degrees past the

limit of what the machine was designed for. This has been a relatively simple modification

that has let us cut tapers as extreme as 45 degrees in any thickness up to 15” tall.